- Project title: MODelling of Advanced LI Storage Systems

- Start date: Juanuary 1st, 2020

- Duration: 36 months

- Grant Agreement number: 875193

- Funded Under: H2020-LC-BAT-2019

- Project website: MODALIS2

Project summary

For a competitive EU battery sector, the development of next-generation battery systems needs cost-efficient processes. MODALIS2 will make a significant contribution to a cost-down for EV battery cells through an all-integrated development process based on numerical tools relying on extensive measurement data and material characterization all the way down to micro-structures. With the integrated modelling and simulation, MODALIS2 will provide degrees of freedom for the cell and battery development processes that allows to address the following design challenges: i) faster development of batteries with higher energy density with new materials; ii) faster development of materials with higher optimized performances for higher-energy battery applications; iii) improved battery safety during transport and operation; iv) optimization of cyclability; v) lower development costs; and vi) better understanding of material interactions within the cell. The main achievement of MODALIS2 is to develop and validate modelling & simulation tools for Gen 3b cells by aiming for higher capacities for the positive & negative electrodes; and for Gen 4b cells by enabling the use of solid electrolytes for improved safety and to facilitate the use of Li-M for the negative electrode. These new technologies are submitted to new specific mechanisms and phenomena (mechanical stresses on negative electrodes, volumetric expansion, solid electrolytic conduction) that are not considered by current modelling and simulation tools. MODALIS2 will address the material characterization of next-generation (3b and 4b) Li-Ion cells in different physical domains, then expanding a carefully chosen set of models towards integrating new cell generations and implementing the models into a numerical simulations toolchain scalable to mass production. The modelling & simulation toolchain will allow faster time-tomarket for next-gen cells.

The consortium has been built on Europe’s best capacities and expertise (industry and research) in the area of experimental characterization of materials, modelling and simulation of cell characteristics as well as manu-facturing of materials and cells for new-generation batteries. The project coordinated by IFPEN includes leading Tier 1 and Tier 2 suppliers, an OEM and research organisations covering the entire value chain of battery developments from materials to integration.

Results achieved

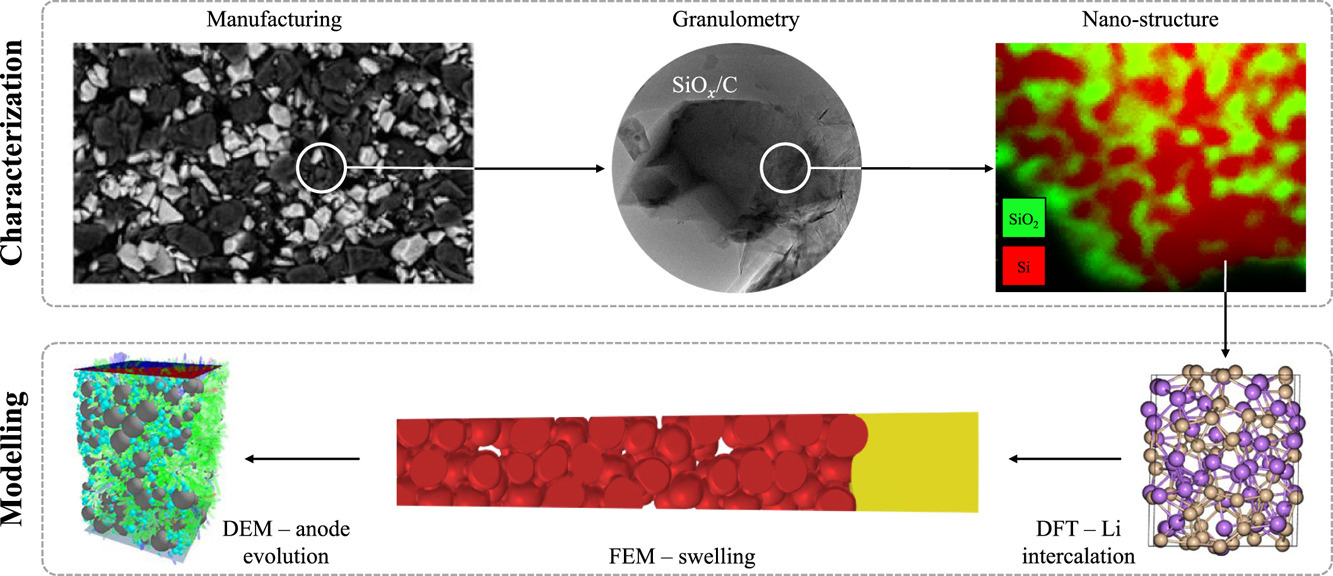

The main role of Gemmate Technologies within the MODALIS2 project is in the implementation of multi-scale models of the battery components at the atomic and mesoscale level. Coupling the use of ab-initio DFT codes and FEM-based modelling Gemmate Technologies aims to bridge the gap between the atomistic-scale chemical information, provided by quantum mechanical results, and the physical models which are the standard for battery simulation in industrial setting. This objective is met through a comprehensive multiscale model of a Si-based composite anode, based on a detailed characterization and encompassing nano-, micro-, and meso-scale details. The model is used to explore the relationship between the chemo-mechanical changes in the anode components and the electrode stability during battery operation, through the prediction of the morphological evolution of the material during the lithiation process. Through the combined analysis of DFT, FEM, and DEM models we highlight the influence of Si and SiO2 lithiation on electrode swelling and damage, and the predominant influence of particle-level morphology on electrochemical behaviour.

Scientific publications

Multiscale modelling of Si based Li-ion battery anodes, Journal of Power Sources 598 (2024) 234109. https://doi.org/10.1016/j.jpowsour.2024.234109