- Project title: Modular laser-based additive manufacturing platform for large scale industrial application

- Start date: October 1st, 2016

- Duration: 36 months

- Grant Agreement number: 723826

- Funded under: H2020-FOF-13-2016 – Photonics Laser-based production

- Project website: MAESTRO

Project summary

Additive Manufacturing (AM) of metal parts has made significant progress over the past two decades, particularly in the field of selective laser melting DMLS (direct metal laser sintering). Today DMLS is considered as a viable alternative for producing near net shape metal components but for relatively small markets where accuracy and surface quality requirements are less stringent. In order to bridge the gap with mass market applications, MAESTRO aims at tackling the current limitations of DMLS in terms of productivity, cost and speed by addressing the following 5 points:

-

Single pre-process software: the numerical chain will be merged into a all-in-one compatible software combining mandatory steps and configurations that are currently split into three different applications to prepare the Additive Manufacturing: importation of CAD files, conversion of geometry in .stl , automatical design of support structures, creation of additive production files, integration of thermo-mechanical simulation of the manufacturing process, topology optimisation.

-

Hybrid MIM / DMLS manufacturing: the fabrication of a preform will be done using MIM (Metal Injection Molding) which will dedicate the DMLS specifically for complex parts requiring greater accuracy and less time use for the more genericparts of the assembly. The objectives are formulating and characterizing metal powders (properties comparable to 90% of the same forged material); mold tooling (reduction of cooling time by 40%) and manufacturing parts with a minimum density of 99% compared to forged material.

-

Adaptive process control: thermal and mechanical on-line monitoring will identify process problems by developing hierarchical process control solutions (in situ monitoring sensors) and integrate in-process 3D measurements for the interfacing of laser AM technologies with complementary post-processing machining technologies. This would guarantee the quality of the products.

-

The modular DMLS additive manufacturing platform: to ensure the good integration of all modules in a platform, these prerequisites will make the link with the existing post-processing procedures, prepare high-resolution data preparation tools and improve the thermal and mechanical properties of the final product. The modular SLM additive manufacturing platform will be tested with characterization samples (tensile, compression, bending, density, hardness, roughness …) to validate the built parts’ quality. The monitoring systems will have to be able to detect the faults and then realise a trigger to stop the production or adapt the laser exposure parameters.

To reinforce the EU leadership in DMLS: an open demonstration platform to reinforce the EU leadership in SLM: In this project, the platform will host the four end-product demonstrators brought by the industrial partners together with three additional ones selected from external companies, through a contest event. The platform will be open to outside companies willing to integrate the project innovation in their future products. A satellite group is already set up for this proposal to gather potential end users at the end of MAESTRO project.

The MAESTRO consortium is a well-balanced consortium with relevant expertise in: SLM for tooling, aerospace, house appliances applications (IPC), Materials and processes (CEA), Manufacturing Engineering (UoB), Software Development (ALTAIR), High precision MIM technologies and equipments (OBE), manufacturing of SLM machines (EOS). Among the consortium, 4 industrial partners: III-V Semiconductors and their packaging (III-V LAB), Sustainable Automotive for Fiat and Chrysler (CRF), Space (Gemmate Technologies), Transport (ALSTOM). The consortium includes the necessary and sufficient number of partners covering all the required interdisciplinary expertise to successfully carry out the required experimentation, integration and demonstration activities as well as to assure a manageable project structure and minimize the risks to achieve the ambitious goals of the project.

Our role

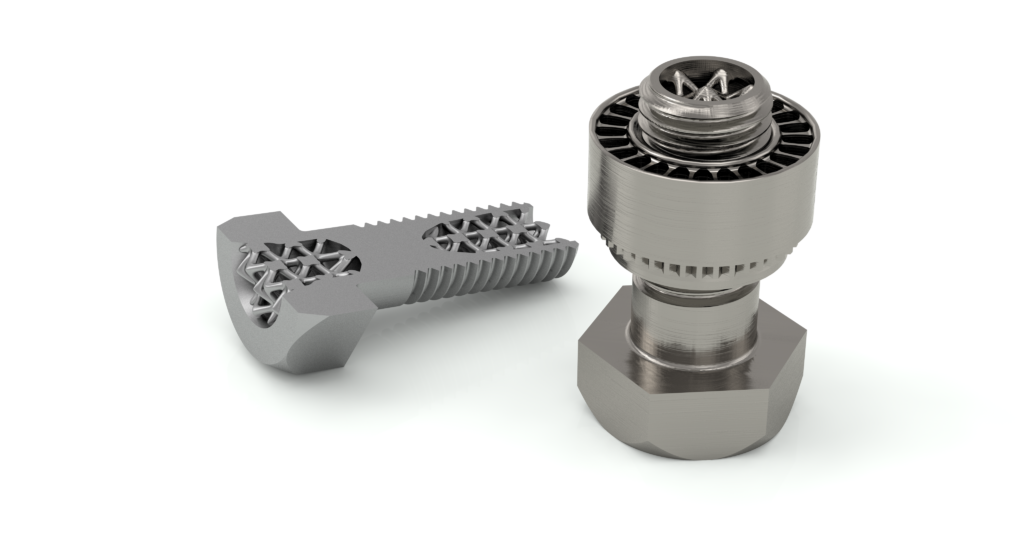

Fasteners for the aerospace industry are becoming components always more demanding the best in class solutions that technology can offer to maintain/improve mechanical and thermal stresses resistance while decreasing weight turning into additional cost any time that module are launched to space. Within this project, novel design concept are investigated to produce Highly Stressed Fastener (hereinafter HSF) lighter in weight with improved mechanical properties. Such HSFs are used for connecting thin metal panels assembling the payload of a satellite, as well as for locking devices or components such as transmitters and solar arrays to the structural parts of orbital bodies, both for interior and exterior uses. In the upcoming future, the space industry envisages to launch also the connecting mechanical components when launching the devices or parts of new generation sent to space to refurbish the orbital bodies. Since these components, all together, represent a significant part of the rocket shipping load (up to 5% of weight), also their weight shall be decreased and treated as an important voice of the overall economical balance of a launch. To this end, Gemmate Technologies aims to develop HSF significantly lighter in weight and still compliant with an assembling in microgravity conditions. The AM re-design, developed by using the optimization process contained in the Altair’s suite, exhibits a significant weight reduction (26.2%) with respect to the normal production counterpart.

An economic assessment over the entire product life cycle is performed during the project. The economic impact of employing the MAESTRO enabled manufacturing platform on the product performance, production efficiency and the efficient use of resources is analysed. In addition, the market potential of MAESTRO platforms for penetrating the larger volume sectors from high to low end product development is assessed.

The technology here developed allows novel design of fasteners, impossible to be conceived within the constraints of conventional manufacturing, thus pushing in this way the design envelope to focus only to satisfy the component mission.

Scientific publications

Influence of Surface Preparation and Heat Treatment on Mechanical Behavior of Hybrid Aluminum Parts Manufactured by a Combination of Laser Powder Bed Fusion and Conventional Manufacturing Processes, Metals 2021, 11(3), 522; https://doi.org/10.3390/met11030522